by Mike Roddy and Dr. Reynaud Serrette. Roddy is a former builder/developer who works for a commercial solar business. Serrette is an Associate Professor of Civil Engineering at Santa Clara University.

The climate-conscious home builder may ask him or herself: “What’s the most C02-friendly method of building a home?” We wanted to find that out as well, so we compared three different materials — steel, timber and concrete.

Surprisingly, it’s not timber. The answer is steel, which has a CO2 Index of 1 compared to 1.52 for concrete and a 4.44 for a timber-framed home.

Here’s how we found the answer by using a single-story, ranch-style house in Texas with three bedrooms, two baths and a garage for a model. The living space was approximately 116 square meters, plus an attached 47 square meter garage and storage area.

The structural systems for all three construction materials were designed by professional engineers. Contractors then developed cut lists and block totals from engineered drawings.

For the steel version of the house, two different approaches were taken: standard profiles, using mostly 0.84 mm material for field framing and high tensile strength (60 ksi) steel combined with more advanced geometries. We then obtained an average total steel weight figure from the two designs. Wood sheathing for the roof was not included, since these elements would be identical for all three houses.

For the wood house, two general contractors (unknown to each other) were asked to develop lumber takeoffs based on the US prescriptive code, and the totals were averaged. We added a standard 15% for lumber yard and site cull. By using a 25% figure for mill waste, in addition to cull, we arrived at a CO2 emissions estimate with a standard deviation of 2.5 tons of CO2 emissions for the sample house.

The block house was engineered using empirical codes for the same location. We then submitted the drawings to a masonry contractor, who developed a block materials list, plus a wastage allowance. Only one block takeoff was collected, assuming minimal variance in builders’ block totals. A 5% breakage figure was added. The roof was framed in steel, so that total structural emissions could be calculated.

Units of measurement were kilograms of steel, cubic meters for wood, and kilograms for CMU blocks plus steel trusses.

CO2 emissions analysis methodology In the US, industry CO2 emissions are calculated by the respective trade associations, in compliance with EPA reporting requirements. The American steel industry submits emissions reports that are non-controversial. Concrete block manufacturing is more variable, but rough industry emissions averages were obtained from the trade associations. Timber emissions resulting from logging operations are more difficult to calculate. Unlike other countries, the US timber industry reports only net sequestration, so there is no easily obtainable separate category for logging produced emissions. Our approaches for the different material industries follow.

Cold-formed steel emissions estimatesData from the three most recent available years was collected: 2006, 2007, and 2008. Tonnage was averaged for these years, yielding a figure of 93.8 million metric tons (Mmt).

Average annual CO2 emissions for the US steel industry for 2006–2008 were 111.7 Mmt per year1. This overall industry figure, with a CO2 emissions intensity of 1.19, was used to calculate emissions for the steel elements in the Texas house. While emissions vary among different mills, we used the average US industry figure.

CMU industry emissions estimates2006 concrete emissions, for both process and energy use, were reported at 70.21 Mmt CO2 in EPA reports to the Energy Information Agency2. The market share of CMU is not available, so we relied on recommended weight formulas in order to estimate annual emissions. The weight of CMU block for the sample house was estimated at 76 metric tons of concrete and mortar. We derived an emissions estimate by calculating 8% emissions by weight of CMU. Steel trusses for the CMU house were added to the total emissions burden of the CMU house.

Timber industry emissions estimatesThe US timber industry does not directly report logging emissions to the Intergovernmental Panel on Climate Change. Values were arrived at through several methods: assessing comparable softwood timber producers’ reported emissions, in this case Canada and Sweden3, evaluating rough submittals in EPA annexes4 and relying on the professional literature. One such study by Heath and Birdsey, US Forest Service carbon scientists, estimated the long term sequestration value of a no logging scenario in the US would save 1.203 billion tons of CO2 emissions annually5.

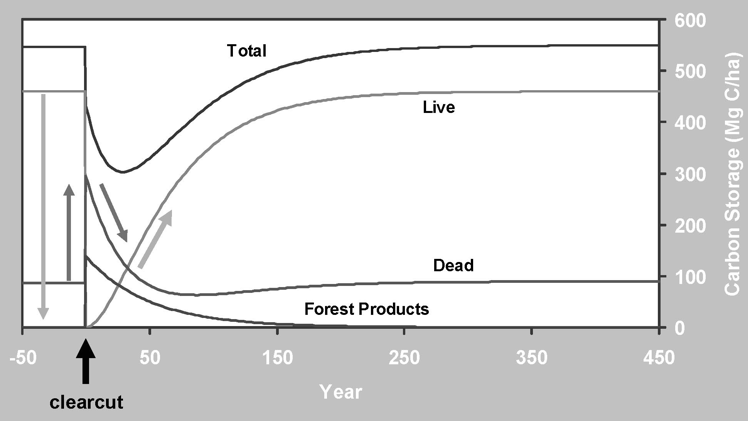

The below illustrates forest carbon flux after a clear-cut harvest. Note that the site vegetation does not begin to achieve net sequestration for many years, since wood products, slash, and litter are decaying faster than growth. It takes 200 years or more before the site sequesters the amount of carbon held previously.

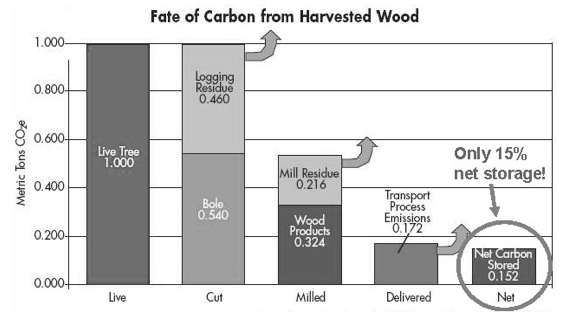

CO2 intensity for logging is roughly estimated at 0.96 Mmt of CO2 per cubic meter of industrial roundwood production, based on typical country forestry emissions reports. The US Department of Agriculture6 reported 2005 US wood products consumption at 599,523 cubic meters, a figure which includes consumption of imported wood products. US CO2 emissions from consuming wood products are estimated at 575.5 Mmt annually. This figure does not include site emissions from soil, and follows Kyoto protocols in not allowing for harvested wood products (HWP) sequestration. The reason for not allowing HWP sequestration is that the wood is replacing wood products that have decayed. HWP carbon sequestration is only 15% of site emissions according to accepted forest carbon science calculations.

Emissions estimate for sample houseSlightly different methods were used to arrive at each structural material’s CO2 emissions score reported in Table 1. Since plywood roof sheathing is assumed to be identical for each house, this material was not included in the emissions calculations. Steel and masonry calculations are roughly accurate, but there are minor uncertainties in the timber calculation, which are reflected in the standard deviation.

Long term trends will favor steel, as energy intensity is declining, and less so timber, since climate disruption is increasing tree mortality worldwide. Degraded forest habitat from industrial logging is a significant factor in this mortality, which has doubled in the US since 1970, but this is not factored into the above emissions calculations.

The American housing industry has an historic opportunity to make substantial contributions toward reducing CO2 emissions into the atmosphere. In a rational world, the outcome would be to switch to inert materials for structural components. Homes would last longer, resist wind, fire, and earthquakes better, and enable the return of robust American forests.

— Mike Roddy and Dr. Reynaud Serrette. Roddy has developed environmental impact analyses for Nucor Steel and the American Iron and Steel Institute. Prof. Serrette has been involved in light frame construction in North America for the past 23 years and he is currently involved in the development of sustainable (materially and economically) light building systems for the Caribbean basin.

JR: I do think that, as with all life-cycle analyses, different assumptions can lead to different conclusions. If one could be confident of sustainably harvesting wood, that would change the equation, as one recent study found. Of course, one might ask, shouldn’t sustainably harvested wood be compared to recycled steel. Systems impacts are also complex. So I’m very open to people coming to different conclusions depending on the choices they make. I generally trust the choices that the US Green Building Council’s LEED certification makes and recommend you do so also when constructing a building. They apparently are tough on wood, especially wood that isn’t certified by the Forest Stewardship Council. I will pursue this further. This post has been updated.References

[1] American Iron and Steel Institute, March 2010 private communication re EPA submittals.[2] US Energy Information Administration, 2007 Emissions and Sinks[3] UNFCC, “Estimation, Reporting, and Accounting of Harvested Wood Products”, GCCC/7P/2003/7, Oct 2003[4] US Environmental Protection Agency, 2007, LULUCF & Annex 3, Table 200[5] Heath and Birdsey, “Carbon trends of productive temperate forests of the coterminous United States”, Water, Air, and Soil Pollution, Volume 70, Oct. 1993[6] United States Department of Agriculture, Statistical Tables, 2007